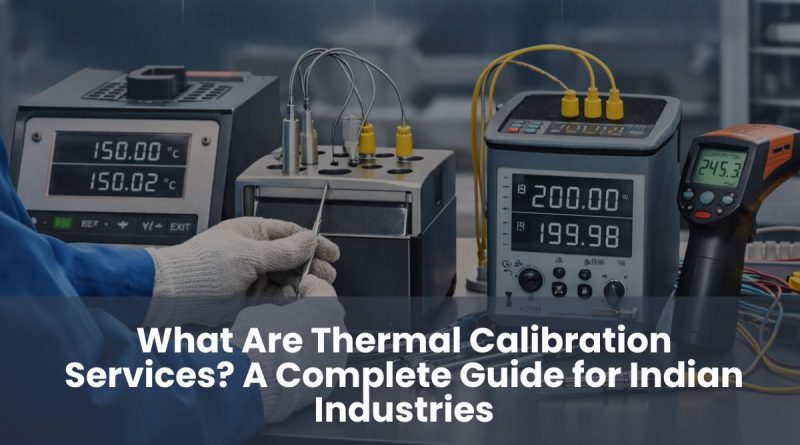

What Are Thermal Calibration Services? A Complete Guide for Indian Industries

In today’s precision-driven industrial landscape, accuracy is not optional—it’s critical. Whether it’s manufacturing, pharmaceuticals, food processing, or energy sectors, temperature measurement plays a vital role in ensuring quality, safety, and compliance. This is where thermal calibration services in India come into play.

This comprehensive guide explains what thermal calibration is, why it matters, how it works, and what industries should know before choosing a service provider.

What Is Thermal Calibration?

Thermal calibration is the process of verifying and adjusting temperature-measuring instruments—such as thermocouples, RTDs (Resistance Temperature Detectors), infrared thermometers, and temperature sensors—against a known and traceable standard.

In simple terms, it ensures that your instruments are giving accurate temperature readings. Even minor deviations can lead to product defects, safety risks, or regulatory non-compliance.

Why Thermal Calibration Is Important

1. Ensures Product Quality

Industries like pharmaceuticals and food processing rely heavily on precise temperature control. Calibration ensures consistent product quality and safety.

2. Regulatory Compliance

Many industries in India must comply with standards such as NABL (National Accreditation Board for Testing and Calibration Laboratories), ISO, and GMP guidelines. Regular calibration is mandatory for audits.

3. Reduces Operational Risks

Incorrect temperature readings can cause equipment failure, spoilage, or safety hazards.

4. Improves Efficiency

Accurate instruments help optimize processes, reduce wastage, and improve productivity.

Types of Instruments That Require Thermal Calibration

Thermal calibration services typically cover a wide range of instruments, including:

- Thermocouples

- RTDs (Resistance Temperature Detectors)

- Digital thermometers

- Infrared thermometers

- Temperature gauges

- Data loggers

- Environmental chambers

Reliable thermal calibration services in India ensure all these devices perform within acceptable accuracy limits.

How Thermal Calibration Works

The calibration process follows a systematic approach:

Step 1: Comparison with Standard

The device under test (DUT) is compared with a reference standard that is traceable to national or international standards.

Step 2: Controlled Environment

Calibration is performed in controlled environments such as dry block calibrators, oil baths, or temperature chambers.

Step 3: Measurement and Recording

Multiple readings are taken at different temperature points to identify deviations.

Step 4: Adjustment (if required)

If discrepancies are found, adjustments are made to bring the instrument within acceptable limits.

Step 5: Certification

A calibration certificate is issued, documenting accuracy, deviations, and compliance.

Industries That Need Thermal Calibration in India

Thermal calibration is essential across various sectors:

1. Pharmaceutical Industry

Precise temperature control is critical for drug formulation and storage.

2. Food & Beverage Industry

Maintains hygiene standards and prevents spoilage.

3. Automotive Industry

Ensures quality control in manufacturing processes.

4. Power & Energy Sector

Used in turbines, boilers, and power plants for operational efficiency.

5. Chemical & Process Industries

Temperature accuracy is crucial for chemical reactions and safety.

Choosing the best thermal calibration services in India helps these industries maintain compliance and operational excellence.

Frequency of Calibration

Calibration frequency depends on:

- Type of instrument

- Usage intensity

- Industry standards

- Environmental conditions

Typically, instruments are calibrated every 6 to 12 months. However, critical applications may require more frequent calibration.

Thermal Calibration Standards in India

India follows strict calibration standards to ensure accuracy and reliability:

- NABL Accreditation

- ISO/IEC 17025 Compliance

- BIS (Bureau of Indian Standards) guidelines

Working with top thermal calibration services ensures adherence to these standards and better audit readiness.

Thermal Calibration Services Price

One of the most common questions industries ask is about cost.

The thermal calibration services price varies depending on:

- Type of instrument

- Number of devices

- Calibration range

- On-site vs. lab calibration

- Accreditation requirements

Estimated Price Range:

- Basic calibration: ₹300 – ₹1,000 per instrument

- Advanced calibration: ₹1,000 – ₹5,000+ per instrument

- On-site services: Additional charges may apply

While cost is important, accuracy and certification should always be the top priority.

On-Site vs. Laboratory Calibration

On-Site Calibration

- Conducted at your facility

- Saves downtime

- Ideal for large or fixed equipment

Laboratory Calibration

- Performed in controlled environments

- Higher accuracy

- Suitable for sensitive instruments

Many thermal calibration services offer both options depending on your needs.

How to Choose the Right Thermal Calibration Service Provider

Selecting the right partner is crucial. Here are key factors to consider:

1. Accreditation

Ensure the provider is NABL-accredited.

2. Experience

Look for providers with industry-specific expertise.

3. Equipment & Technology

Advanced calibration tools ensure higher accuracy.

4. Turnaround Time

Fast service minimizes operational downtime.

5. Certification

Proper documentation is essential for audits.

Working with top thermal calibration services in India guarantees reliability and compliance.

Common Challenges in Thermal Calibration

Despite its importance, industries often face challenges such as:

- Lack of awareness about calibration schedules

- Choosing non-accredited providers

- Ignoring minor deviations

- Delayed calibration cycles

Addressing these issues can significantly improve operational efficiency.

Benefits of Regular Thermal Calibration

Regular calibration offers long-term advantages:

- Improved product quality

- Enhanced safety standards

- Reduced equipment downtime

- Compliance with regulatory norms

- Increased customer trust

Investing in thermal calibration services is not just a compliance requirement—it’s a strategic business decision.

Future of Thermal Calibration in India

With the rise of automation, IoT, and Industry 4.0, thermal calibration is evolving rapidly. Smart sensors, digital calibration systems, and remote monitoring are becoming more common.

Indian industries are increasingly adopting advanced calibration techniques to stay competitive globally.

Conclusion

Thermal calibration is the backbone of accuracy in industrial operations. From ensuring product quality to meeting regulatory standards, its importance cannot be overstated.

By choosing the best thermal calibration services in India, businesses can ensure precision, compliance, and long-term reliability. Whether you’re in manufacturing, pharmaceuticals, or energy, regular calibration is essential for sustainable growth.

Understanding the process, costs, and benefits will help you make informed decisions and maintain the highest standards in your operations.

Source: https://ronetechlabs.wordpress.com/2026/02/19/thermal-calibration-services-guide-indian-industries/